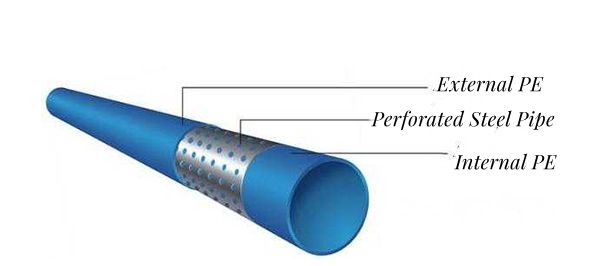

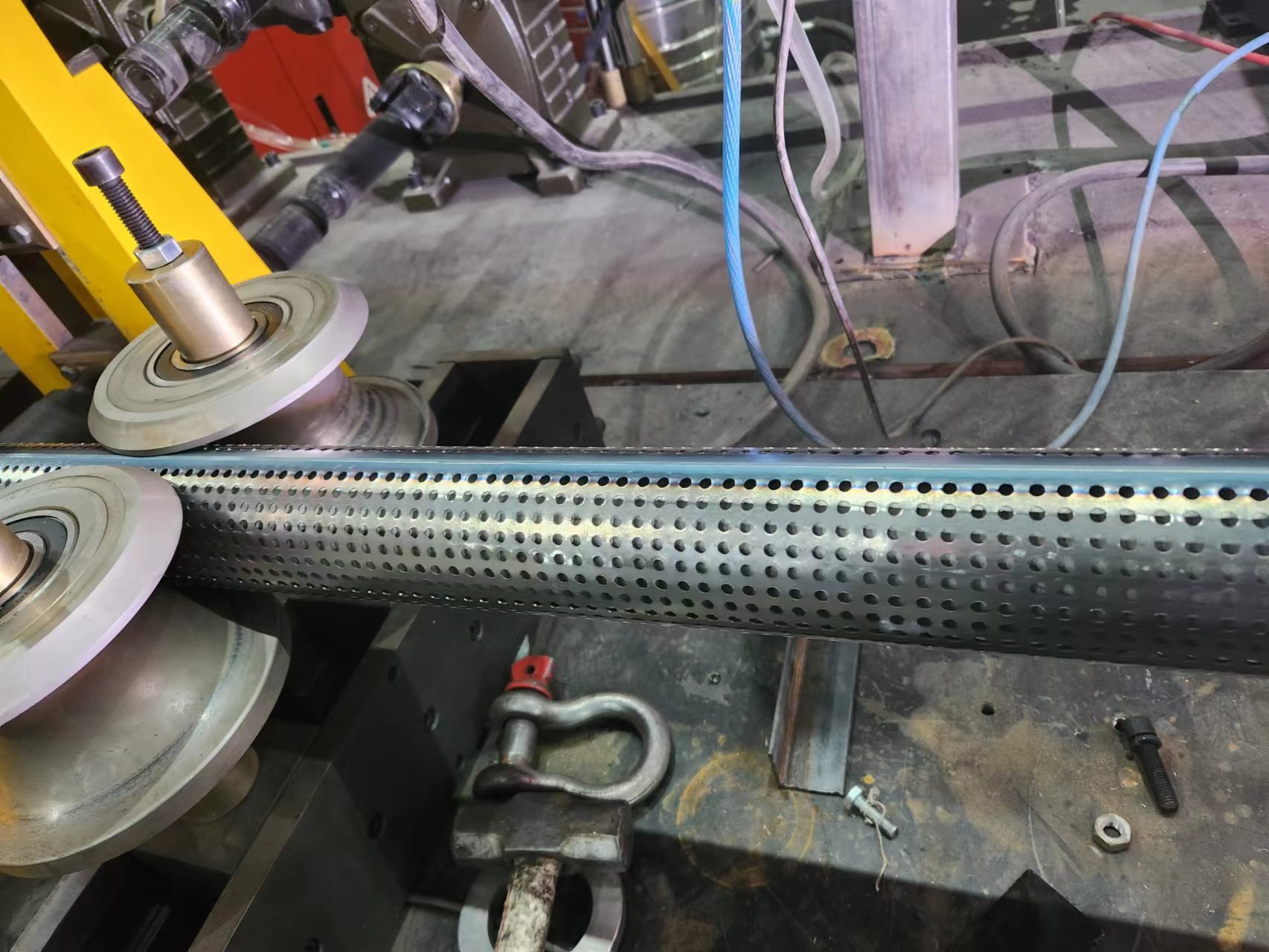

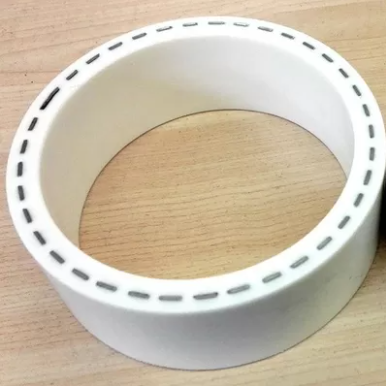

Perforated steel belt polyethylene composite pipe production line

Perforated steel belt polyethylene composite pipe production line

polyethylene composite pipe production line

Model | Pipe Diameter(mm) | Machine Speed(m/h) | Capacity(km/y) | Power(KW) |

|---|---|---|---|---|

What's The Main Business In Your Company?

The main products are PE/PPR/PVC pipe production lines,WPC/PVC profile produciton lines,PET bottles and PP/PE films recycling line,Plastic wastes pelletizing lines, and all kinds of otherauxiliary equipments,such as Mixer,Crusher,Pulverizer,Shredder,Water Chiller and so on.

Can you tell me your payment way and delivery and guarantee time?

1. Delivery Time: 30 working days after receiving your down payment.

2. Payment Condition: 30% by T/T for deposit and 70% by T/T before delivery time. 3.Guarantee: 12 months for the machine (the electric parts for 6 months).During this guarantee period, FOSITA will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, FOSITA will provide the buyer spare parts at cost price.How about your arrangement for inspection,installation and testing work?

1. After all machines are delivered to customer's factory;

2. FOSITA will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory. 3.The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance for each engineer. 4.Engineer will give free training lessons to labors in buyer's factory.Where Is Your Company And Factory Address?

We are in Yongli industrial zone,Leyu town,Zhangjiagang city,Jiangsu Province,and it's near to Shanghai,only 1 hour driven by highspeed trai

- *Name

- *Tel

- *Title

- *Content

Just tell me what you want, a customized product is welcome!

contact us- Name:

- TOM

- Tel:

0086-512-58663008

0086-512-58660733

- Email:

- fosita03@cnfosita.com

- WhatsApp:

- https://wa.me/8613606229132