Home / All / Plastic Pipe Extrusion Machine /

Fosita 160-400mm Plastic PE HDPE Pipe Making Machine Extrusion Production Line

Fosita 160-400mm Plastic PE HDPE Pipe Making Machine Extrusion Production Line

Detail Information

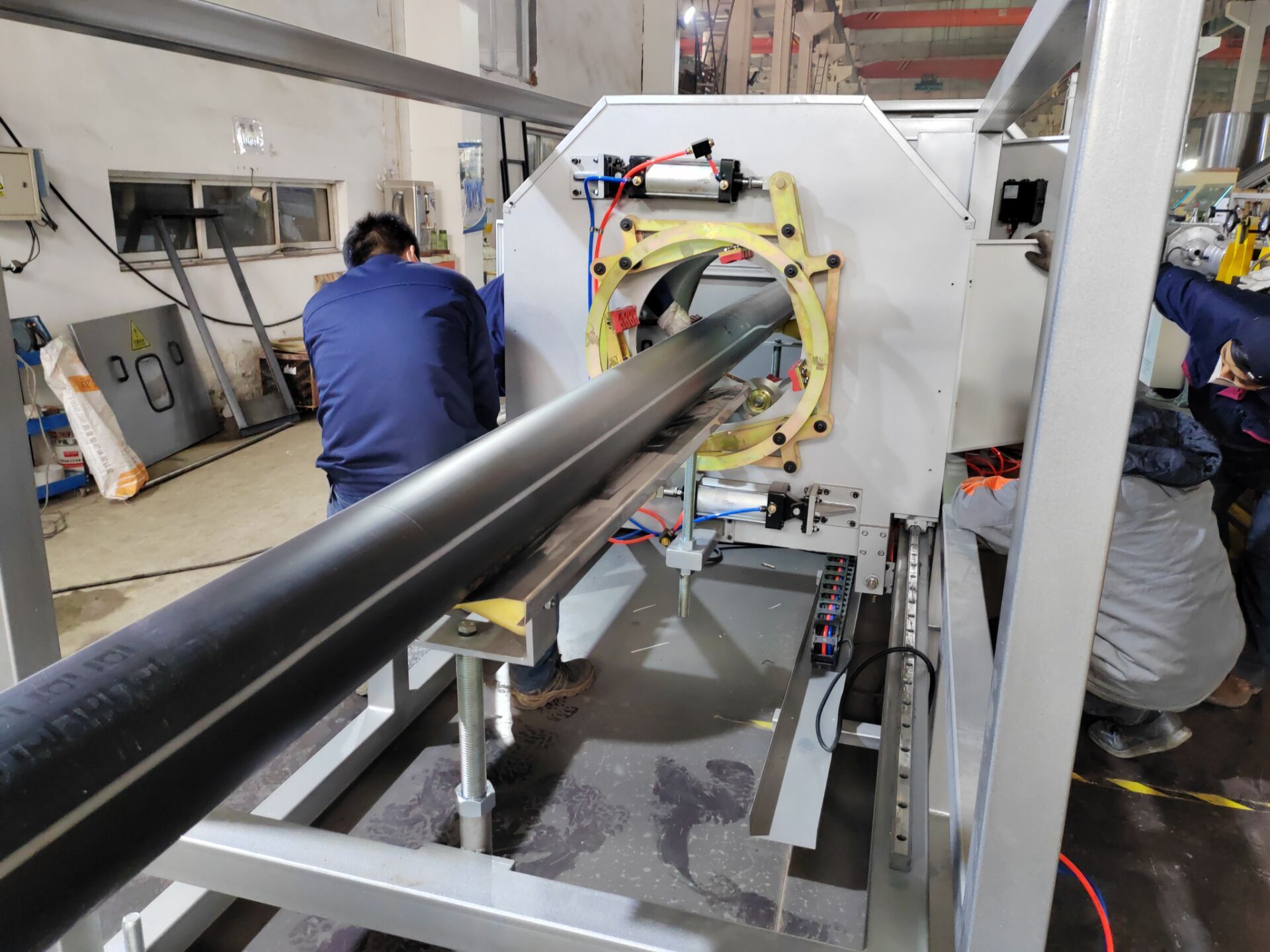

160-400mm PE Pipe Making Machine

PE pipe making machine

1.The pipes are extruded by the first extruder and then enter the twist form machine, at the same time the basket co-extrusion mould forms pipes' shape.

2.The pipes are based on high density PE as main raw material.

Process line

Raw material+master batches→mixing → vacuum feeding → material dryness → single screw extruder → basket co-extrusion mould → calibrator → spray vacuum calibration tank → spray cooling water tank → belt haul-off → single screw glue extruder → winder → winding roller forming → water cooler → pipe rack → finished product inspecting&packing

|

Pipe diameter range(mm)

|

Extruder Model

|

Extruder Power(KW)

|

Max.Output (KG/H)

|

|

50-110

|

65/33

|

55

|

180

|

|

75-250

|

75/33

|

110

|

330

|

|

160-450

|

90/33

|

165

|

450

|

Main advantage

1.This kind of pipes have many advantages, such as corrosion resistant light, easy to fix, long time to use etc.

2.The pipes are widely used in high-way, municipal constructional, flats and so on.

2.The pipes are widely used in high-way, municipal constructional, flats and so on.

Related Products

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Just tell me what you want, a customized product is welcome!

contact usnavigation

Contact Person

- Name:

- TOM

- Tel:

0086-512-58663008

0086-512-58660733

- Email:

- fosita03@cnfosita.com

- WhatsApp:

- https://wa.me/8613606229132

E-mail Subscriptions

QR code