Home / All / Plastic Pelletizing&Granulating System /

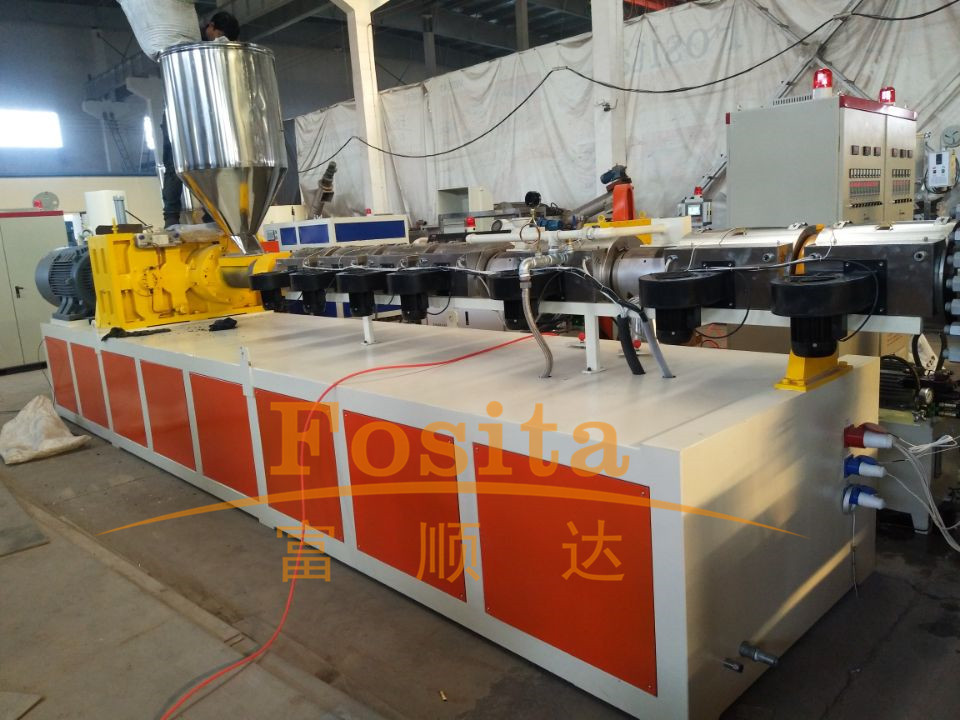

Double Stage Recycling and Pelletizing Machine

Double Stage Recycling and Pelletizing Machine

Detail Information

Product Description

★ Fosita is the professional manufacturer and experience supplier for waste plastic recycling and pelletizing making machine.

★ This two-stage granulating machine contains a sub-extruder to process dirty or printed materials. This is our highly recommended model for not only its capability of processing both hard and soft plastics but its user-friendliness for one-person easy operation. Also, it only takes two hours for operating and maintenance training.

★To reduce the source waste and make profit.Keep the environment clean, and reduce to be broken the environment secondly.

Applicable Plastics

Material:PVC,PE,PP,ABS,PA,HDPE,LDPE,PET,etc,.

Material Shapes: All kinds of plastic material such as film,woven bags,raffia and flakes.

Double Stage plastic Pelletizing Machine List

|

No.

|

Name

|

Quantity

|

|

1

|

Screw Loader

|

1 set

|

|

2

|

Mother Extruder

|

1 set

|

3 | Hydraulic Screen Changer | 1 set |

4 | Baby Extruder | 1 set |

5 | Hydraulic Screen Changer | 1 set |

6 | Pelletizing Mould | 1 set |

|

7

|

Water Tank

|

1 set

|

8 | Water Take-off Unit | 1 set |

9 | Cutting-Unit | 1 set |

10 | Cyclone Storage | 1 set |

Product Details

★ This model is two stage type which uses oil hydraulic screen changer to change the filter more easily and promptly.

★ It equipped with a force feeding hopper to ensure the crushed films drops stably into the barrel.

★ If we don't have budget for crusher, we can choose side feeding hopper to help us achieving feeding perfectly.

Hydraulic Screen Changer

★ The main die mould has a special design to get the vent effect and let the melted resin drops smoothly into the hopper.

Working Video

Technical Parameter

|

Pipe Line Model

|

Extruder Model

|

Output(kg/h)

|

Line Length(m)

|

|

FST-200

|

SJ100/100

|

200-300

|

13

|

|

FST-300

|

SJ200/200

|

350-400

|

20

|

|

FST-500

|

SJ150/150

|

450-600

|

25

|

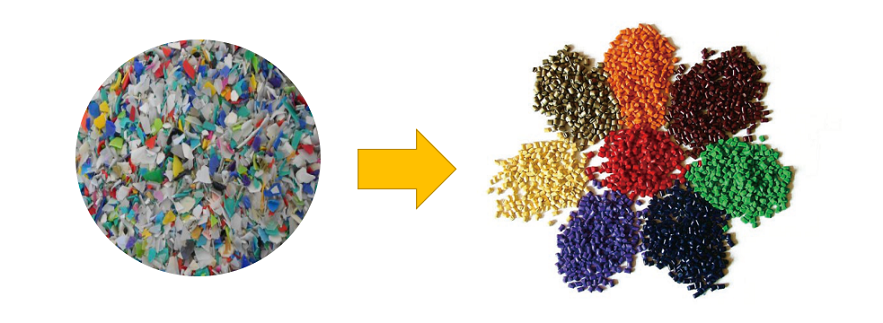

Final Products

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Just tell me what you want, a customized product is welcome!

contact usnavigation

Contact Person

- Name:

- TOM

- Tel:

0086-512-58663008

0086-512-58660733

- Email:

- fosita03@cnfosita.com

- WhatsApp:

- https://wa.me/8613606229132

E-mail Subscriptions

QR code