Home / All / Plastic Pelletizing&Granulating System /

PP/PE Recycling and Water-ring Granulating Machine Line

PP/PE Recycling and Water-ring Granulating Machine Line

Detail Information

Products Description

★ This plastic recycling and water-ring granulating system is suitable for many waste film recycling and making pellets,such as PP, HDPE, LDPE film and clean woven bag material, etc,.

★ This film can be cut and compressed in agglomerator and then feed into extruder.According to our design,we make sure this machine has a long working life and ecnomical efficiency in using.

★ You can choose use single stage or double stage plastic film granulating machine according to how clean your material.

Plastic Films

Woven Bags

Plastic Bags

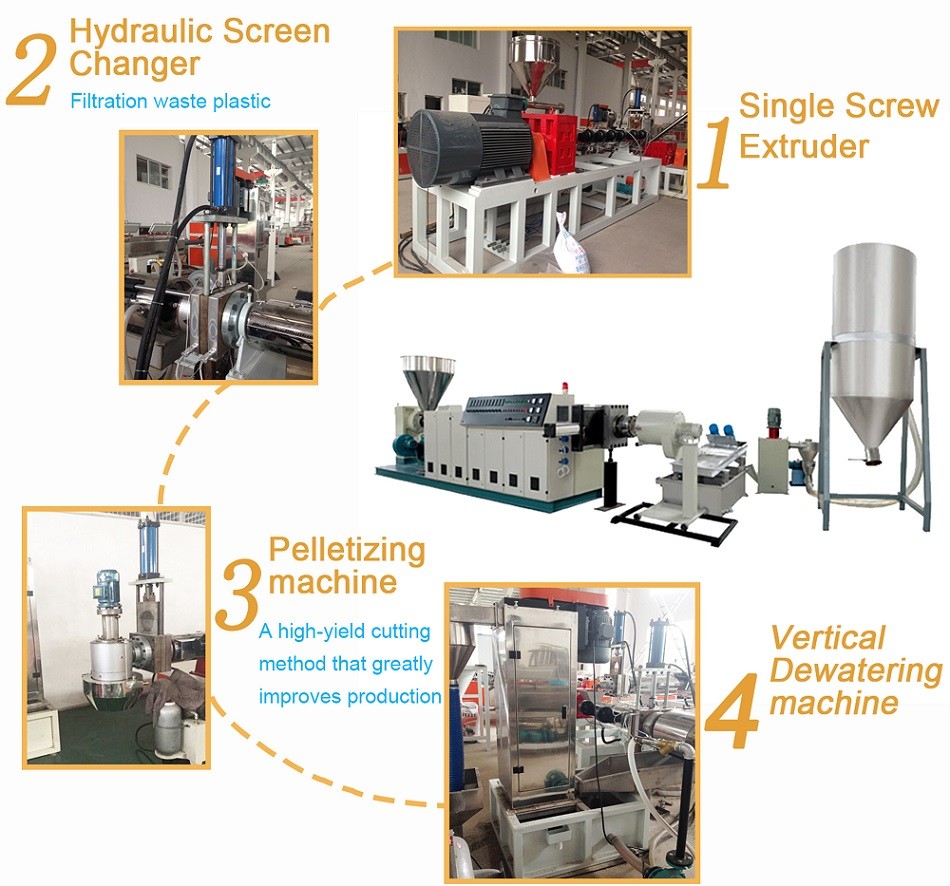

Working Procedure

Technical Parameters

|

Pipe Line Model

|

Extruder Model

|

Output(kg/h)

|

Line length(m0

|

|

FST-150

|

SJ100

|

80-150

|

12

|

|

FST-300

|

SJ120

|

200-300

|

18

|

|

FST-500

|

TSK95

|

400-500

|

22

|

Working Video

Final Products

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Just tell me what you want, a customized product is welcome!

contact usnavigation

Contact Person

- Name:

- TOM

- Tel:

0086-512-58663008

0086-512-58660733

- Email:

- fosita03@cnfosita.com

- WhatsApp:

- https://wa.me/8613606229132

E-mail Subscriptions

QR code