Home / All / Plastic Pelletizing&Granulating System /

Plastic Pelletizing Machine with Compactor Design Granulating System Manufacturer Fosita Company

Plastic Pelletizing Machine with Compactor Design Granulating System Manufacturer Fosita Company

Detail Information

Product Description

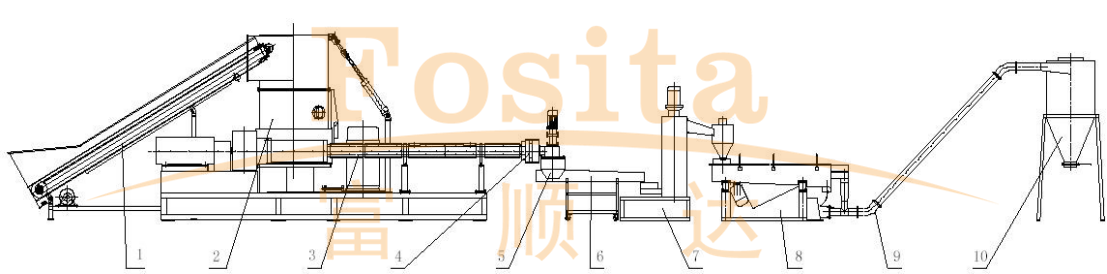

This plastic pelletizing machine can used for granulating many kind of raw material such as plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

Final productions are in the form of pellets/granules, which can directly put into the production line for blowing moulding machine, plastics injection machine, etc.

Working Process

|

No.

|

Machine Name&Type

|

Quantity

|

Remark

|

|

1

|

Belt Conveyor

|

1 Set

|

Film Feeding

|

2 | Compactor | 1 Set | Film Compactor |

3 | Single Screw Extruder | 1 Set | Venting System |

4 | Hydralic Screen Changer | 1 Set | Non-stop changing the net |

|

5

|

Water-ring Cutter

|

1 Set

|

Horizontal or Vertical

|

|

6

|

Spin-Dryer

|

1 Set

|

Vertical Type

|

Process flow of plastic granulating machine :

Convey feeder→Compactor→Extruding machine→ High speed screen exchanger→ water-ring pelletizing machine (or strand cutting)→Spin Dryer → Storage silo

Technical Parameter

|

Pipe Line Model

|

Extruder Model

|

Output(kg/h)

|

Line Length(m)

|

|

FST-150

|

SJ100

|

200

|

10

|

|

FST-300

|

SJ120

|

550

|

15

|

|

FST-500

|

SJ150

|

1000

|

20

|

Suggestions for you

We suggest you choose suitable machines according to your capacity, material and other requirements.

After machine tested and been delivered to your factory. We can also provide training service for your workers with experienced engineers.

So if you're looking for plastic granule making pelletizing machine, please contact us without any hesitation.

We'll provide better quality machine and better service for you.

Please send your message to us

- *Name

- *Tel

- *Title

- *Content

Just tell me what you want, a customized product is welcome!

contact usnavigation

Contact Person

- Name:

- TOM

- Tel:

0086-512-58663008

0086-512-58660733

- Email:

- fosita03@cnfosita.com

- WhatsApp:

- https://wa.me/8613606229132

E-mail Subscriptions

QR code