New Designed 16-63mm PVC Two Cavity Double Pipe Making Machine

16-63mm PVC Two Cavity Double Pipe Making Machine

product desciption:

1.Replacement mould can produce pipes with different diameters.

2.With a set of mould to produce one out of two or four tubes at the same time.Increased production efficiency.

3.More cost-effective production line.

4.Greatly saving the use of the factory space.

5.High energy efficiency.Just a set of power systems.

6.Can significantly reduce the number of operators.

7.Simple operation.

1.Replacement mould can produce pipes with different diameters.

2.With a set of mould to produce one out of two or four tubes at the same time.Increased production efficiency.

3.More cost-effective production line.

4.Greatly saving the use of the factory space.

5.High energy efficiency.Just a set of power systems.

6.Can significantly reduce the number of operators.

7.Simple operation.

Introduction:

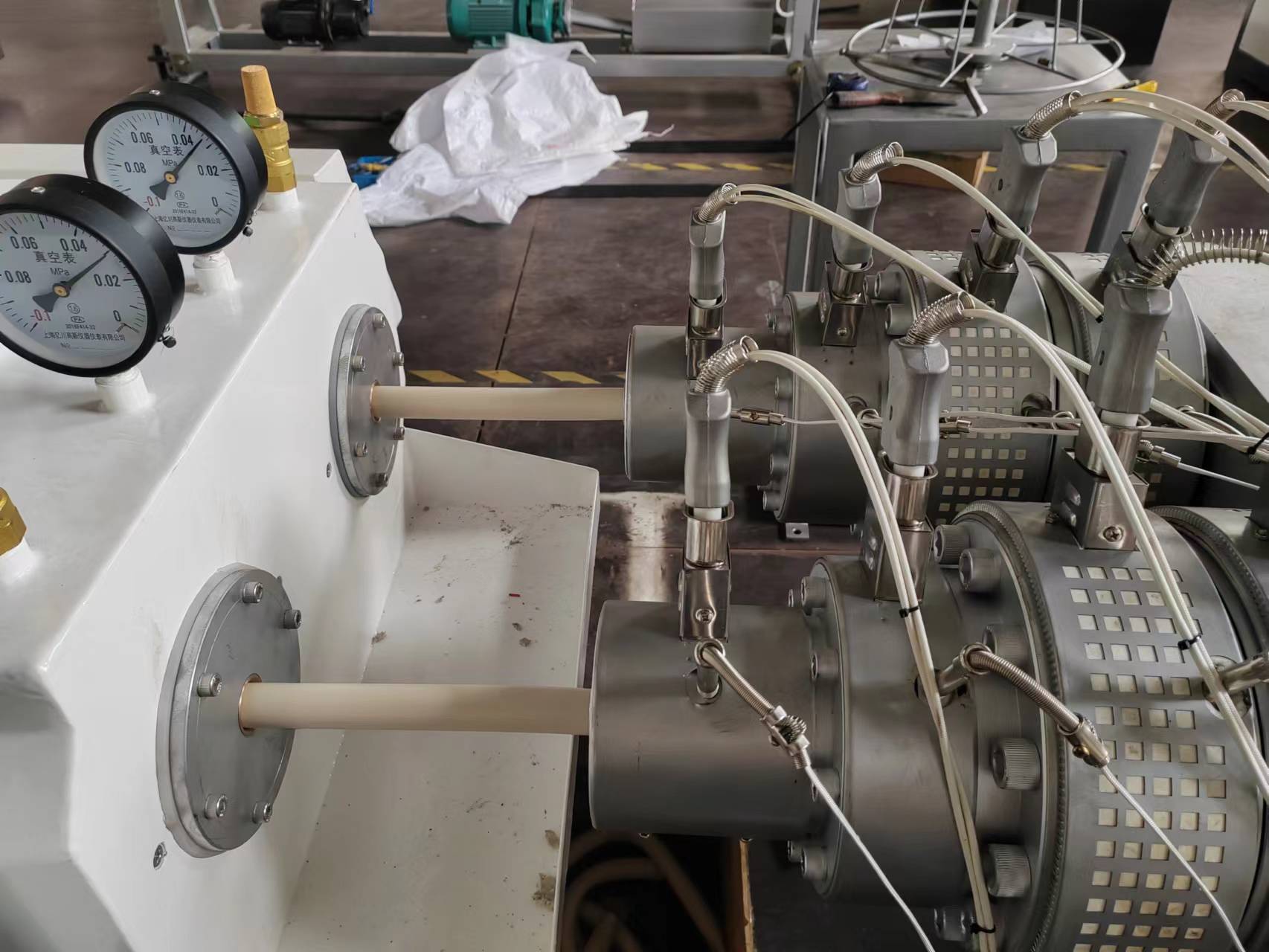

1 .The full electrical pvc pipe production machine include one double screw extruder SJZ55 or SJZ65, Mould based on pipe diameter, Vacuum Tank, Haul-off& cutter, Stacker.

2. On this pvc water waste pipe making machine you want to produce CPVC pipe, you can add one system called die core temperature adjust system, and must be with water cooling, as CPVC has special chemical character than UPVC;

3. For electrical pvc pipe production machine, the capacity can be 150kg/h, 200kg/h, 300kg/h and 500kg/h, you can choose them based on your needs, then we will suggest the satisfied extruder and auxiliary machines; You can check different capacity of extruder from below form:

4.Used for Water Supply Pipe&Drainage pipe&Sewage Pipe

PVC Pipe processing flow:

Raw Material &additive → Heating Cooling Mixer →Material Feeding → Forced feeding → Conical Double Screw Extruder →Extruder Mould &Calibrator → Vacuum Calibration Cooling Tank → (Spray Cooling Tank) → Ink Printer → Double belt Haul-off → Double uplift Cutter → Double pipe Stacker

1 .The full electrical pvc pipe production machine include one double screw extruder SJZ55 or SJZ65, Mould based on pipe diameter, Vacuum Tank, Haul-off& cutter, Stacker.

2. On this pvc water waste pipe making machine you want to produce CPVC pipe, you can add one system called die core temperature adjust system, and must be with water cooling, as CPVC has special chemical character than UPVC;

3. For electrical pvc pipe production machine, the capacity can be 150kg/h, 200kg/h, 300kg/h and 500kg/h, you can choose them based on your needs, then we will suggest the satisfied extruder and auxiliary machines; You can check different capacity of extruder from below form:

4.Used for Water Supply Pipe&Drainage pipe&Sewage Pipe

PVC Pipe processing flow:

Raw Material &additive → Heating Cooling Mixer →Material Feeding → Forced feeding → Conical Double Screw Extruder →Extruder Mould &Calibrator → Vacuum Calibration Cooling Tank → (Spray Cooling Tank) → Ink Printer → Double belt Haul-off → Double uplift Cutter → Double pipe Stacker

We are Suzhou Fosita Science and Technology Company Limited.Fosita is located in Zhangjiagang city,Jiangsu Province,China,which is near Shanghai city by 1 hour by high speed train to come.

Fosita is the factory of plastic pipe production line,plastic profile production line,plastic recycling machine,plastic granulating machine with more than 20 years exporting experiences.

Fosita is specialized in the manufacturing,processing in assembling of plastic extruder technology with professional engineer and sales team.Delicate to strict quality control and thoughtful customer service,our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.